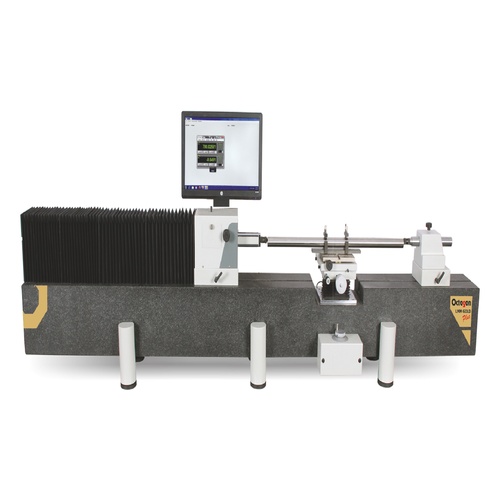

Universal Length Measuring Machine LMM 400

Price 1350000.0 INR/ Number

Universal Length Measuring Machine LMM 400 Specification

- Usage

- LMM 400 specially designed for calibration of internal / external plain and thread gauges including taper gauges, measuring devices like internal / external micrometers, precision dial indicators etc

- Type

- Other

- Dimension (L*W*H)

- 850x250x470 mm Millimeter (mm)

- Weight

- 70kg Kilograms (kg)

- Equipment Materials

- Machine Base is made of Cast Iron

- Power

- 230 V 50Hz Volt (v)

- Voltage

- 230 V 50Hz Volt (v)

- Application

- LMM 400 specially designed for calibration of internal / external plain and thread gauges including taper gauges, measuring devices like internal / external micrometers, precision dial indicators etc

- Warranty

- 1 Year

Universal Length Measuring Machine LMM 400 Trade Information

- Minimum Order Quantity

- 1 Number

- Delivery Time

- 8 Week

- Packaging Details

- Wooden Packaging

- Main Domestic Market

- All India

About Universal Length Measuring Machine LMM 400

A model of universal length measuring machine specially designed as standard quality assurance tool in general engineering industry and reference instrument for gauge calibrations.

Machine horizontal base is made of rugged cast-iron with guide-ways for the measuring head and the tailstock positioning.

Absolute Measuring Range: 100mm

Differential Measuring Range: 400mm

Resolution: 0.1m

Display System: Machine is interfaced with Octagon ULM Inspect gauge measurement and management software / DRO (Digital read-out system).

Precision Calibration Simplified

With the Universal Length Measuring Machine LMM 400, intricate gauge and instrument calibration is executed with unmatched accuracy. Essential for metrological labs and quality assurance departments, it handles internal and external plain, thread, and taper gauges, as well as delicate measuring devices. This ensures that your measurements consistently meet required standards and tolerances.

Robust Construction and User-Friendly Design

Built on a stable cast iron base, the LMM 400 delivers both durability and vibration resistance for sustained precision. Its compact frame allows easy integration into most workspaces, making it a versatile addition to calibration labs and manufacturing settings. The intuitive interfaces minimize operator effort and maximize productivity.

FAQs of Universal Length Measuring Machine LMM 400:

Q: How does the LMM 400 facilitate calibration processes?

A: The LMM 400 employs advanced precision mechanisms to accurately calibrate a variety of devices including internal and external gauges, micrometers, and dial indicators. Its stable cast iron base and precision engineering minimize measurement error, streamlining calibration procedures for repeatable and reliable results.Q: What specific devices can be calibrated using the LMM 400?

A: The machine is designed for calibrating internal/external plain and thread gauges, taper gauges, micrometers, and precision dial indicators, covering a broad spectrum of measurement tools commonly used in manufacturing and metrology labs.Q: When should the LMM 400 be used in a calibration workflow?

A: The LMM 400 is best utilized during scheduled tool calibration sessions or after tool repair, ensuring all measurement devices maintain accuracy before being put into service or production environments.Q: Where is the LMM 400 typically installed and used?

A: This device is commonly installed in metrology laboratories, manufacturing plants, and quality assurance departments, particularly in industries requiring stringent measurement standards such as automotive, aerospace, and engineering.Q: What is the process for using the LMM 400 for calibration?

A: Operators securely mount the device to be calibrated on the LMM 400s base, align it according to the required measurement parameters, and follow precise software-guided steps to achieve and verify calibration, complying with relevant standards.Q: What benefits does the LMM 400 offer over manual calibration methods?

A: By providing automated, high-accuracy calibration, the LMM 400 reduces human error, increases efficiency, and ensures reliable traceability in measurement, which is crucial for quality control and industry certification.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Universal Length Measuring Machine Category

Universal Length Measuring Machine LMM 40

Warranty : 1 Year

Equipment Materials : Cast Iron

Application : LMM 40 Measuring Machine Designed for Measurement of Precision Parts and Calibration of Gauges

Power : 230V 50Hz Volt (v)

Voltage : 230 Volt 50 Hz Volt (v)

Dimension (L*W*H) : 560x220x360 Millimeter (mm)

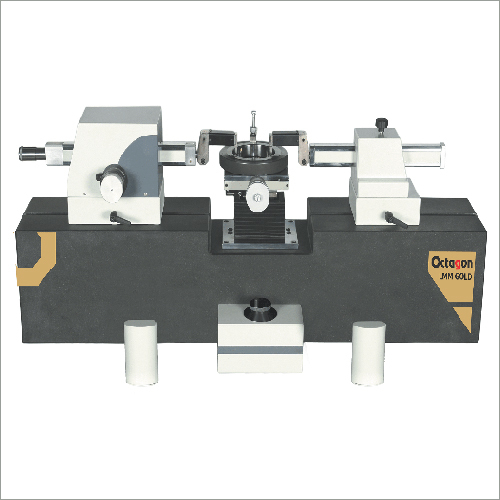

Universal Length Measuring Machine - LMM Gold Plus 800 / 1600

Warranty : 1 Year

Equipment Materials : Machine Base is made of Precision Granite for Structural Stability and minimising effect of temperature variations

Application : LMM Gold Plus specially designed for calibration of internal / external plain and thread gauges including taper gauges, measuring devices like internal / external micrometers, precision dial indicators etc

Power : 230 V 50Hz Volt (v)

Voltage : 230 V 50Hz Volt (v)

Dimension (L*W*H) : 1560 / 2350 x 380 x 500 mm Millimeter (mm)

Universal Length Measuring Machine - LMM 100

Warranty : 1 Year

Equipment Materials : Machine Base is made of Cast Iron

Application : LMM 100 specially designed for calibration of internal plain and thread measurements by using single arm.

Power : 230 V 50Hz Volt (v)

Voltage : 230 V 50Hz Volt (v)

Dimension (L*W*H) : 600x250x470 Millimeter (mm)

Universal Length Measuring Machine LMM Gold

Warranty : 1 Year

Equipment Materials : Machine Base is made of Precision Granite for Structural Stability and minimising effect of temperature variations

Application : LMM Gold specially designed for calibration of internal / external plain and thread gauges including taper gauges, measuring devices like internal / external micrometers, precision dial indicators etc

Power : 230 V 50Hz Volt (v)

Voltage : 230 V 50Hz Volt (v)

Dimension (L*W*H) : 1100x380x500 mm Millimeter (mm)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS