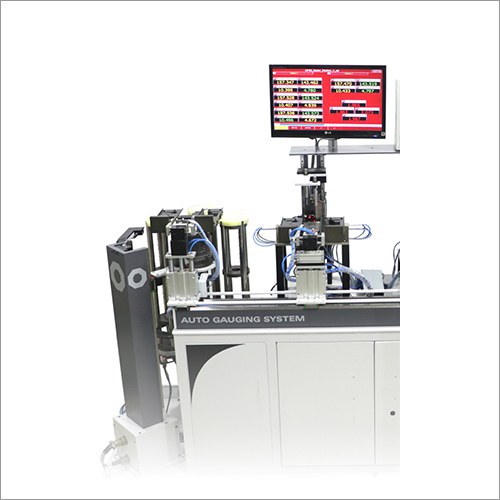

Automatic Gauging System

Automatic Gauging System Specification

- Thread

- standard

- Outer Size

- standard

- Measuring Range

- standard

- Grade

- standard

- Application

- Pharmaceutical Manufacture, Mechanical Engineering, Water Engineering, Textile Industry, Marine Engineering

Automatic Gauging System Trade Information

- Payment Terms

- Letter of Credit (L/C), Western Union, Telegraphic Transfer (T/T), Cheque, Cash Advance (CA)

- Delivery Time

- 8 Week

- Packaging Details

- Wooden Packaging

- Main Domestic Market

- All India

About Automatic Gauging System

PLC/CNC controlled automatic / semi automatic measurement program which caters to emerging needs of Industry 4.0requirements.Measurement system offered with customised design suitable for measurement of multiple parameters in single operation.Offered with non-contact type air gauging, laser sensors or contact type precision inductive probes, or combination of air gauging + laser sensors + inductive sensors depending upon requirement.Computerised data processing for derived parameters and geometric feature derived by using 3D co-ordinate metrology software.Possibility to integrate with existing component handling line Gantry or line conveyor.Ability to communicate with the CNC machines, Robots, Gantry and Marking machines / Scanners simultaneously for complying the requirements of Industry 4.0.Can parallelly communicate to ioT softwares and SPC softwares for cloud computing.Standard shop floor applications for mass production of automobile or engineering parts like connecting rod, cylinder head, engine block, crank shaft, cam shaft etc.FAQs of Automatic Gauging System:

Q: What industries can the Automatic Gauging System be applied to?

A: The Automatic Gauging System is suitable for Mechanical Engineering, Water Engineering, Pharmaceutical Manufacture, Marine Engineering, and the Textile Industry.Q: Does the Automatic Gauging System support standard thread specifications?

A: Yes, the Automatic Gauging System supports standard thread specifications.Q: What is the grade classification of the Automatic Gauging System?

A: The Automatic Gauging System is designed with a standard grade classification.Q: What are the dimensions of the Automatic Gauging System?

A: The Automatic Gauging System features a standard outer size.Q: What is the measuring range of the Automatic Gauging System?

A: The Automatic Gauging System is equipped with a standard measuring range.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Gauging System Category

Gauging Station System For Shop Floor

Case : Standard

Outer Size : Standard

Thread : Standard

Display : Monitor

Frequency : Standard

Grade : Standard

Semi Automatic Gauging System

Case : Standard

Outer Size : Standard

Thread : Standard

Display : Standard

Grade : Standard

Gauging System For Cylinder Head Valve Seat And Cam Bore

Case : Standard

Outer Size : Standard

Thread : Standard

Frequency : Standard

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free